Motorsport

Racing to pole position

Aubert & Duval offers the widest range of high performance materials to meet the most extreme and exacting requirements for every demanding motorsport, including Formula 1, WRC, INDYCar and MotoGP.

Aubert & Duval offers the widest range of high performance materials to meet the most extreme and exacting requirements for every demanding motorsport, including Formula 1, WRC, INDYCar and MotoGP.

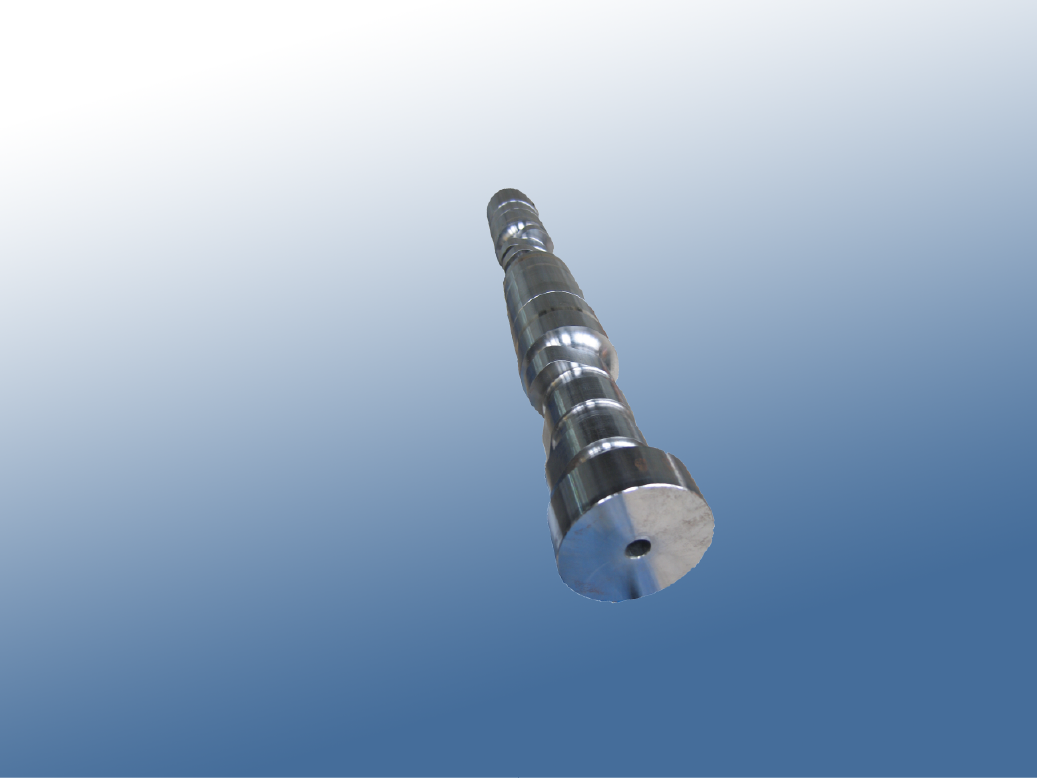

Thanks to its long experience in aerospace applications, Aubert & Duval can supply innovative, reliable solutions for highly demanding parts in critical powertrain and engine applications:

| Parts | Request | Aubert & Duval best-in-class materials |

| Crankshafts | Fatigue mainly

Stiffness Wear |

GKP® deep nitrided

NC310YW carburized |

| Drive shafts

Transmission shafts Torsion bars |

Mandatory: High yield strength

Fatigue, toughness Corrosion if requested |

NC310YW carburized |

| Hot parts | Yield strength at temperature

Fatigue at temperature Creep resistance |

AD730® |

| Fasteners, bolts | High Strength, Fatigue, corrosion | MLX®17, MLX®19 |

In addition, Aubert & Duval produces a wide range of metal powders for additive manufacturing, suitable for motorsport applications.

Material innovation driven by performance

In collaboration with the main racing teams, Aubert & Duval constantly develops new metallurgical solutions to meet their current requirements more closely and anticipate their future challenges. For decades, we have designed a great many high performance steels, providing better mechanical properties including:

- MLX®17 represents an attractive solution for fastening systems, thanks to its mechanical properties: high resistance, excellent fatigue performance and corrosion resistance.

- MLX®19 can be an excellent candidate for drive shafts requiring corrosion resistance. MLX®19 static and fatigue performance will match Maraging 250, which is widely used for chassis and driveshaft parts in all car racing formats.

- GKP®: this CrMoNiV grade melted in VIM/VAR mode, was designed to improve nitriding kinetic initially developed with Eurocopter for gearbox. Associated with deep gas nitriding process, it is recognized as best fatigue performer for rotative parts like crankshaft.

- ML340: Co-developed and patented with Safran Aircraft Engines (LEAP aero-engines), this duplex maraging grade, is particularly recommended for high torque and high fatigue loading shafts thanks to its combination of hardenability and toughness properties, high fatigue performances and nitriding ability

In addition, because the inherent quality of the materials is key to overall performance, Aubert & Duval has a dedicated technical support team for motorsport applications that assists customers in selecting suitable materials and associated heat treatments.