Aubert & Duval is vertically integrated from melting & remelting (with some of the largest triple-melt nickel-base alloy ingots and billets on today’s market) through to forging and machining to near-net shape profiles. We offer one of the largest and most comprehensive capabilities in the design and manufacture of critical closed-die superalloy forgings for land-based turbines.

Typical products for power generation applications:

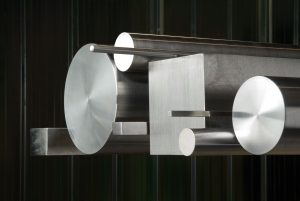

Typical products for power generation applications: The initial quality of the chosen material is key to the part’s final performance. We offer a wide range of products in several forms of

The initial quality of the chosen material is key to the part’s final performance. We offer a wide range of products in several forms of  Combining metallurgical expertise, outstanding industrial capabilities and high manufacturing skill, Aubert & Duval contributes to development programs for advanced generations of steam and gas turbines.

Combining metallurgical expertise, outstanding industrial capabilities and high manufacturing skill, Aubert & Duval contributes to development programs for advanced generations of steam and gas turbines.