Quality

OUR QUALITY COMMITMENTS

Aubert & Duval manufactures high-tech parts for applications as diverse as aerospace, nuclear, defense, medical and motorsport, all industries with stringent expectations of the highest quality standards.

At Aubert & Duval, we are committed to meeting our customers’ expectations by providing high quality alloys and products to support their performance.

Outstanding quality is ensured by the dedication of all our employees at every step in the production process. It is supported by:

- Recognised world-class know-how in metallurgy

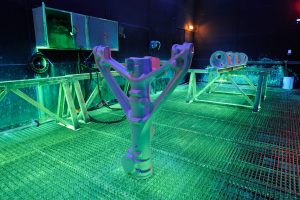

- State-of- the-art facilities with strict maintenance and monitoring

- Laboratory and control facilities for accurate measurements

- Intensive data recording to detect any deviation and provide strict process control

- A continuous improvement spirit supported by a dedicated team and shop floor performance

- management

- Efficient matrix organization driving product / process optimization

At Aubert & Duval, we all strive to meet new challenges and support customers’ developments through the quality of the products we deliver.

QUALITY ASSURANCE

All Aubert & Duval sites maintain quality management systems and comply with the requirements of various industry quality standards.

Quality controls

Quality controls are performed throughout the manufacturing process to target 0 ppm.

– Destructive testing:

- Tensile

- Impact bending

- Hardness

- K1C toughness

- Creep

- Etc.

– Non-destructive testing (NDT)

- Ultrasonic inspection

- Magnetic particle inspection

- Dye-penetrant testing

- Eddy current testing

- X-ray inspection

- Etc.