Due to its low density (4.5 vs. 7.8 for steel) and high resistance to corrosion, titanium has become a popular material for a variety of aerospace applications, whether in engines for disks, blades, shafts and casings or airframe applications such as landing gear, wing beams or fasteners.

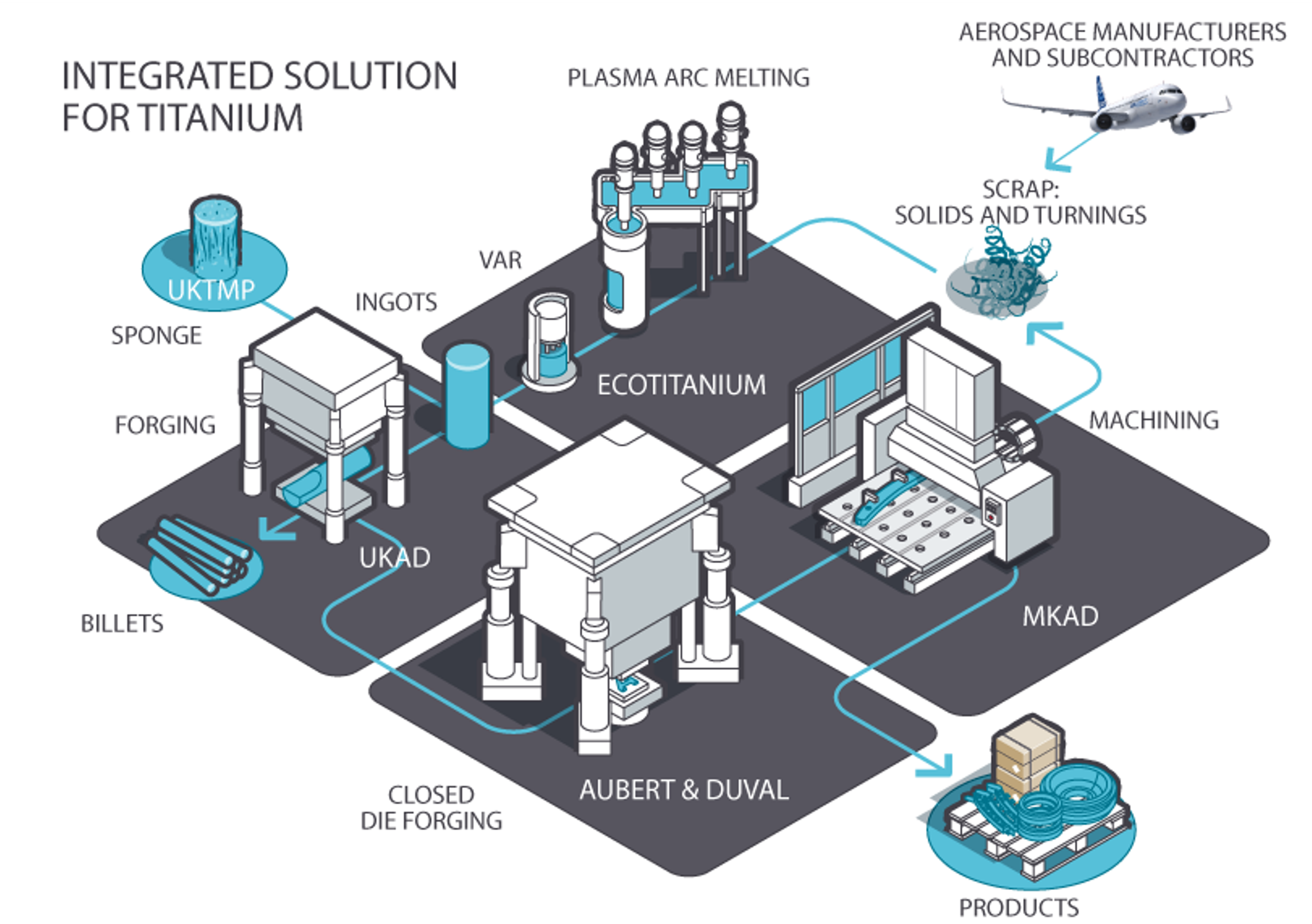

With its fully integrated solution for titanium, Aubert & Duval is a leading global supplier and manufacturer of aviation-grade titanium and titanium alloy products. From melting to finished parts, Aubert & Duval produces high strength titanium alloy products in billets, closed die forgings and machined parts.