Aubert & Duval meets the defense industry’s material requirements for artillery forgings, drawing on extensive, worldwide experience in artillery systems.

Artillery and Military transportation

Caliber

- `Medium calibers: 20 – 76 mm

- Large calibers: 76 – 155 mm

Applications design

Tank gun barrel forgings

Tank gun barrel forgings- Self-propelled howitzer forgings

- Naval guns

- Helicopter and aircraft barrels

- Mortar barrels

Increasing system life

- Aubert & Duval CLARM® grades have the unique ability to:

o Reduce thickness to save weight

o Increase systems’ service life

o Accept more and more powerful ammunitions

- Aubert & Duval has the capability to vertically heat treatment barrels to minimize distortion and residual stresses for artillery forgings, avoiding barrel deformation after firing

- Production capacity can be adjusted in accordance with our customers’ needs

Grade design

Among the steel grades for artillery forgings available from Aubert & Duval, three are especially designed for gun blanks and mortar barrel forgings. They are:

Among the steel grades for artillery forgings available from Aubert & Duval, three are especially designed for gun blanks and mortar barrel forgings. They are:

- CLARM®HBR,

- CLARM®HB3

- CLARMHB7®

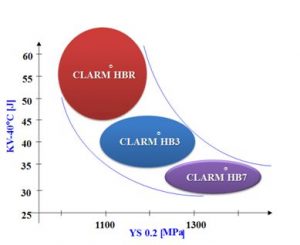

The CLARM® family is famous worldwide for its exceptional combination of tensile strength, ductility and toughness. The steel grade choice is mainly governed by the required compromise between yield strength (YS) and toughness at low temperature (KV-40°C). See adjacent drawing.

Mechanical design

Standard data for the guaranteed minimum mechanical properties of 155L52 or 120L52 barrel blanks (breech side, mid-wall thickness) are shown below. For special requirements please contact us.

Breech block - Breech ring design

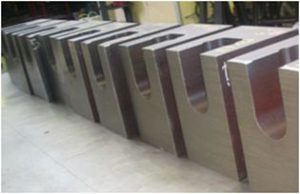

Aubert & Duval also manufactures artillery components such as breech blocks and breech rings. Breech blocks are heavy wall thickness components that require the right steel grade choice to guarantee homogenous mechanical properties throughout the component, and achieve the best possible compromise on tensile strength/ductility and toughness. The CLARM® steel grade family covers a wide range of component sizes and all usual mechanical specifications.

Aubert & Duval also manufactures artillery components such as breech blocks and breech rings. Breech blocks are heavy wall thickness components that require the right steel grade choice to guarantee homogenous mechanical properties throughout the component, and achieve the best possible compromise on tensile strength/ductility and toughness. The CLARM® steel grade family covers a wide range of component sizes and all usual mechanical specifications.

Metal Powders for additive manufacturing

Aubert & Duval can provides metal powders for 3D-printing of manufactured parts for armoured vehicles and artillery applications, find out more

For specific grades, dimensions or applications contact us.

In addition to artillery forgings and breech parts, Aubert & Duval offers advanced materials for mortars.

In addition to artillery forgings and breech parts, Aubert & Duval offers advanced materials for mortars.