World Conference on Titanium 2019

Share

Aubert & Duval, major sponsor of the 14th edition of World Conference on Titanium, from June 10 to 14 in Nantes.

Find us on our Booth 39-40, and come to the conference of Jacques Lecadet :

“Advances and Breakthroughs in Titanium forgings for critical structural parts” :

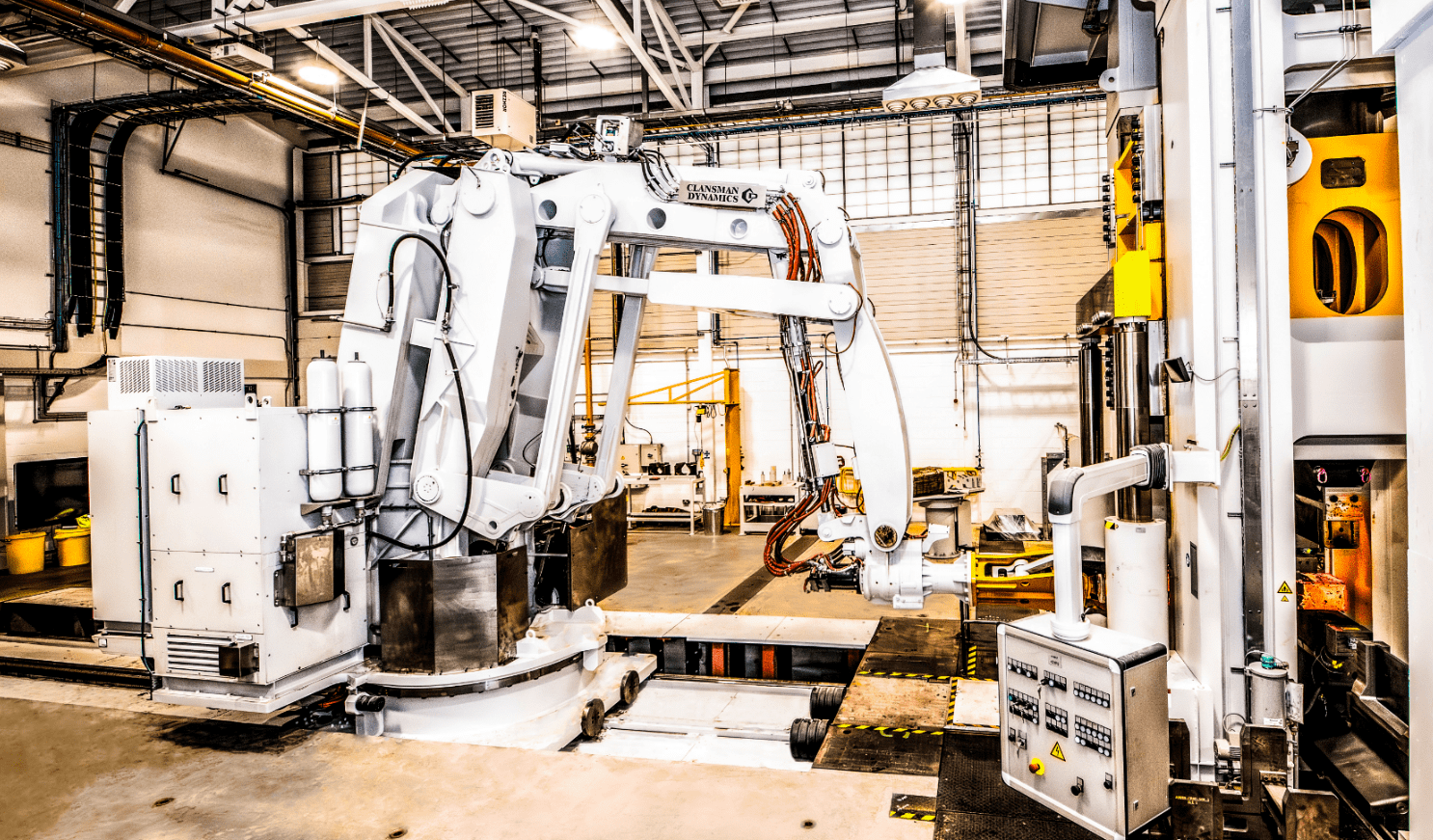

Following several decades of experience in titanium close die forging of structural parts, Aubert&Duval has implemented during the last ten years a fully integrated manufacturing process in order to propose cost optimizations of forgings to its customers. Assuming the high level of the properties and reliability of titanium forgings, strong drivers of research and development for forgings are the pressure on cost, the buy to fly reduction and the life cycle. This presentation discusses the potential of optimizations to address these challenges. The following levers of improvement are presented. The first way to concretely answer the question of the cost and of the life cycle is the recycling of manufacturing scrap and end-of-life products, using the concept of circular economy and implementing a short loop from end user to melters. This is a considerable opportunity to mitigate the risks related to the supply of primary material and to the erratic fluctuations of raw material prices. The second step to optimize both the added value and the material consumption consists in adapting accurately the melting and ingot conversion processes to the actual needs of the application and the subsequent transformation processes. These adaptations can bring significant savings to the cost of billets. Considering the close die forging step, the use of the concept of Design for Manufacturing, or Design for forging in the present case, has also a great potential to optimize the cost and the functions of the forgings. This requires a close cooperation of engineering teams to better manage the constraints of design, integration of functions and manufacturing process. Near Net Shape Forging of titanium, using high temperature close die forging, is also an opportunity to make a breakthrough in terms of buy to fly and to integrate more complex functions in forged parts. In addition to all these improvements, the use of high-power hydraulic presses is a key element to take full advantage of them and to manufacture large critical parts with more functions. All together these levers could provide drastic cost reductions, discussed in this paper, and a considerable reduction in the environmental impact, keeping the intrinsic advantages of titanium forgings in terms of metallurgical integrity, residual stresses and properties. The implementation of these improvements will require continuous efforts of development from the whole titanium supply chain, and collaboration between integrated titanium forgings suppliers and the OEMs.