Product finder

Enhancing your performance

News

See all news

Press release

21.03.2024

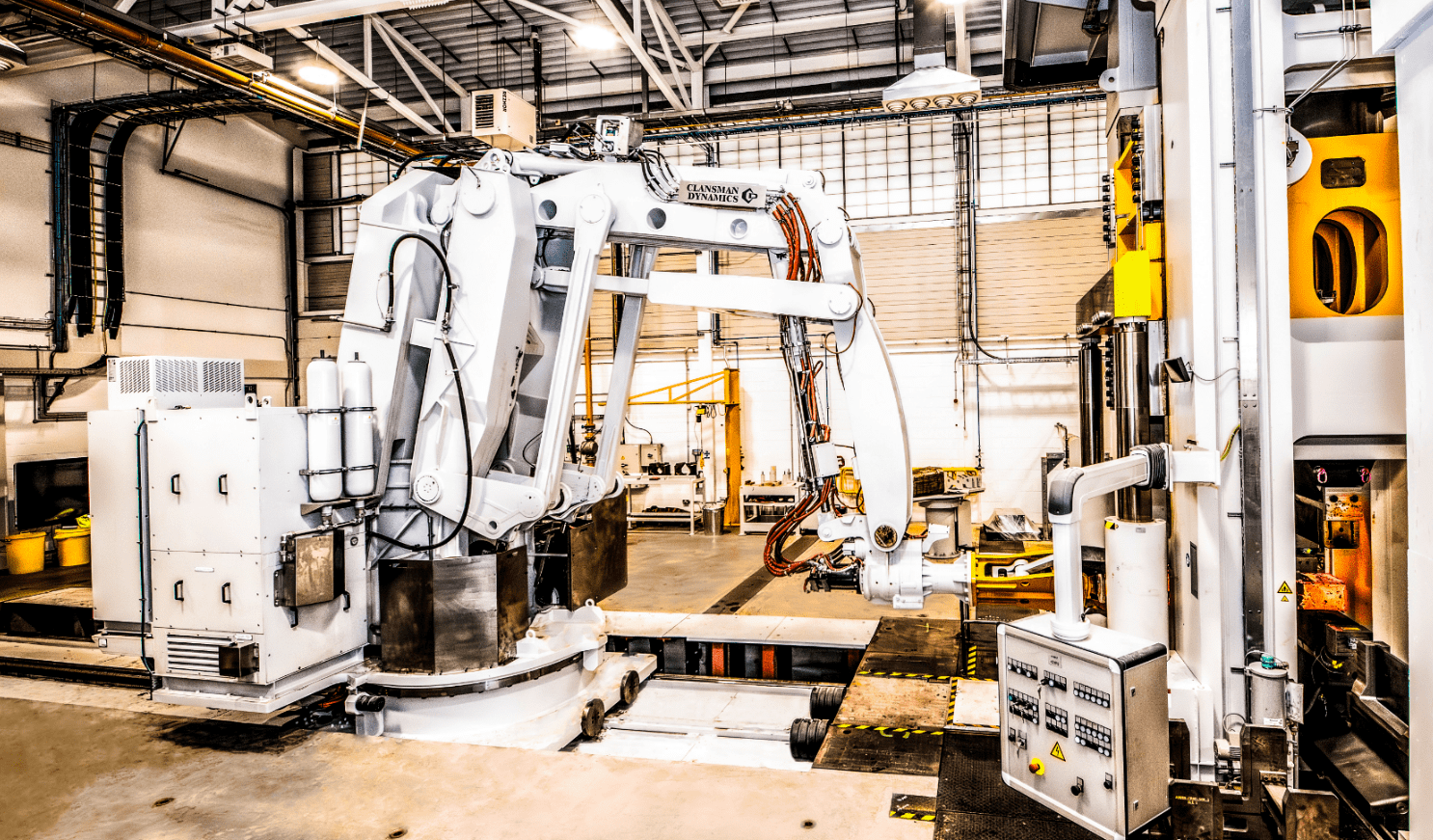

Alongside a long-standing Tier 1 membership, Aubert & Duval supported the official launch of a new multi-function hydraulic press capabil

Who are we

We design, make and process materials to deliver high performance metallurgical solutions in the form of bars, powders, billets, forgings, closed die-forgings, hipped parts or pre-machined parts in high performance steels, superalloys, aluminum and titanium alloys.