SPOTLIGHT: creation of a new heat treatment line Pamiers with the support of French Recovery Plan and the ADEME.

Share

With the support of ⵌFrance Relance and ADEME our goal is to overhaul one of the site’s heat treatment lines to strengthen our competitive positioning in terms of the metals of the future, particularly superalloys.

The special processes employed in heat treatment are a key area of expertise for Aubert & Duval. They enable us to modify the microstructure of our materials and parts to achieve the highest specifications required by our customers. Mastering these processes is central to our industrial mission, which involves working on the most demanding projects (aeronautics, energy, defense, etc.).

Almost all the parts produced in Pamiers undergo heat treatment procedures. These operations take place at a critical moment in the manufacturing cycle, when a lot of value has already been added to our products. Heat treatment performance thus has a major impact in terms of Right First Time, our lead times and our costs.

This investment is also aimed at ensuring our future development. Having a new, fully modernized and automated heat treatment line is vital for increasing our capacity in terms of the materials of the future, particularly superalloys, whose technical specifications are extremely stringent.

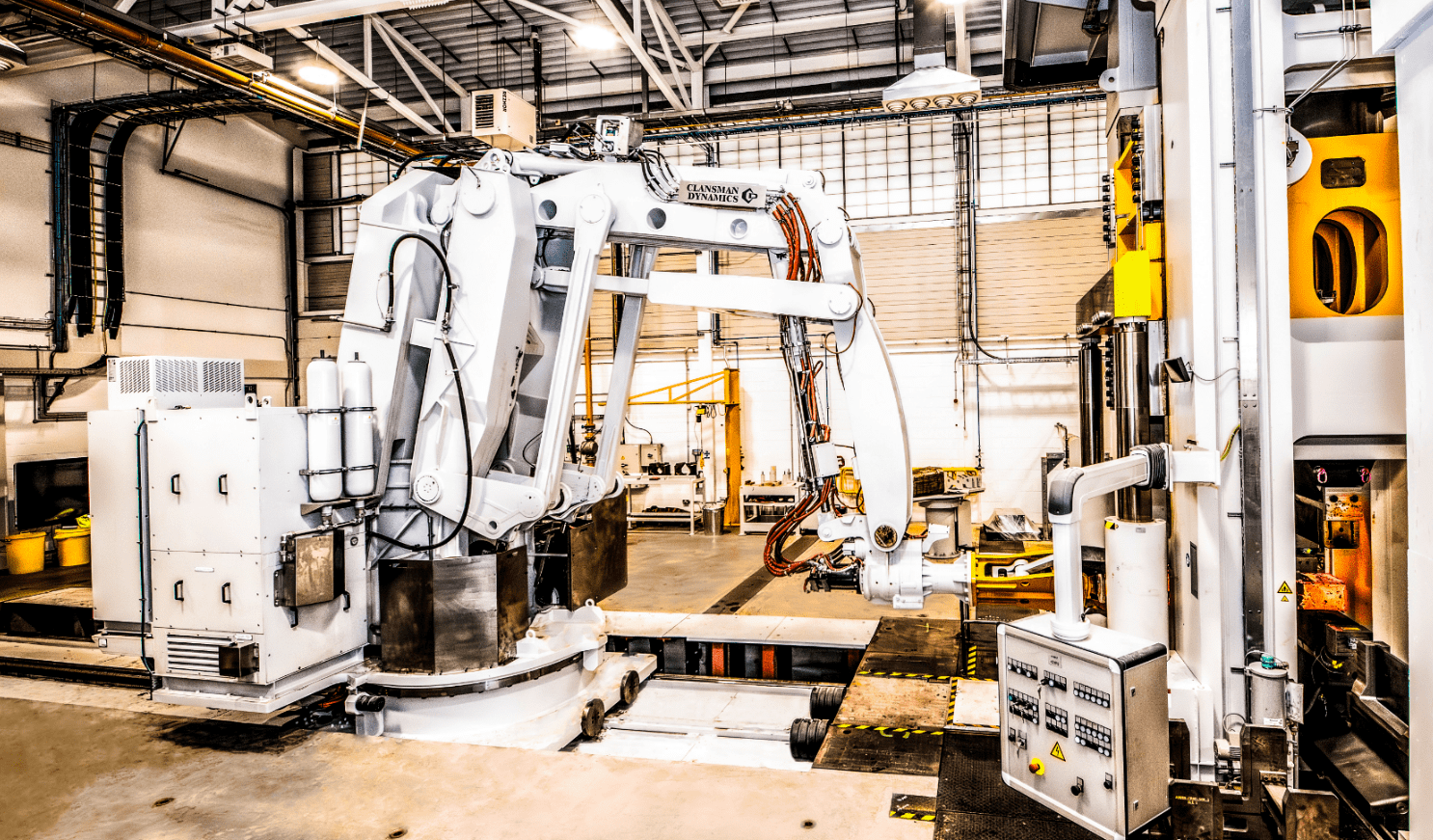

The new line, which will completely replace the current heat treatment line 3, known as the “small line,” has been designed to the highest standards in order to achieve the following objectives:

- Reduction of safety risks and improvement of working conditions thanks to a redesigned layout and the automation of potentially accident-prone processes

- Process and quality control, in particular, thanks to the digitization of our processes

- Productivity and flexibility, with modern tools designed to adapt to the needs of different markets

- Reduction of our environmental footprint, thanks to the use of the latest energy efficiency technologies, with the following benefits: A 6% reduction of energy consumption and an 8% reduction in CO2 emissions across the entire site.

We would like once again to thank our partners at France Relance and the ADEME, whose support will enable us to make the leap into Industry 4.0.