EcoTitanium recycles Titanium

Share

80% recycled. This is the percentage of titanium turnings and chips used to produce EcoTitanium ingots. This plant is the first in Europe to manufacture aerospace quality titanium alloys from recycled material.

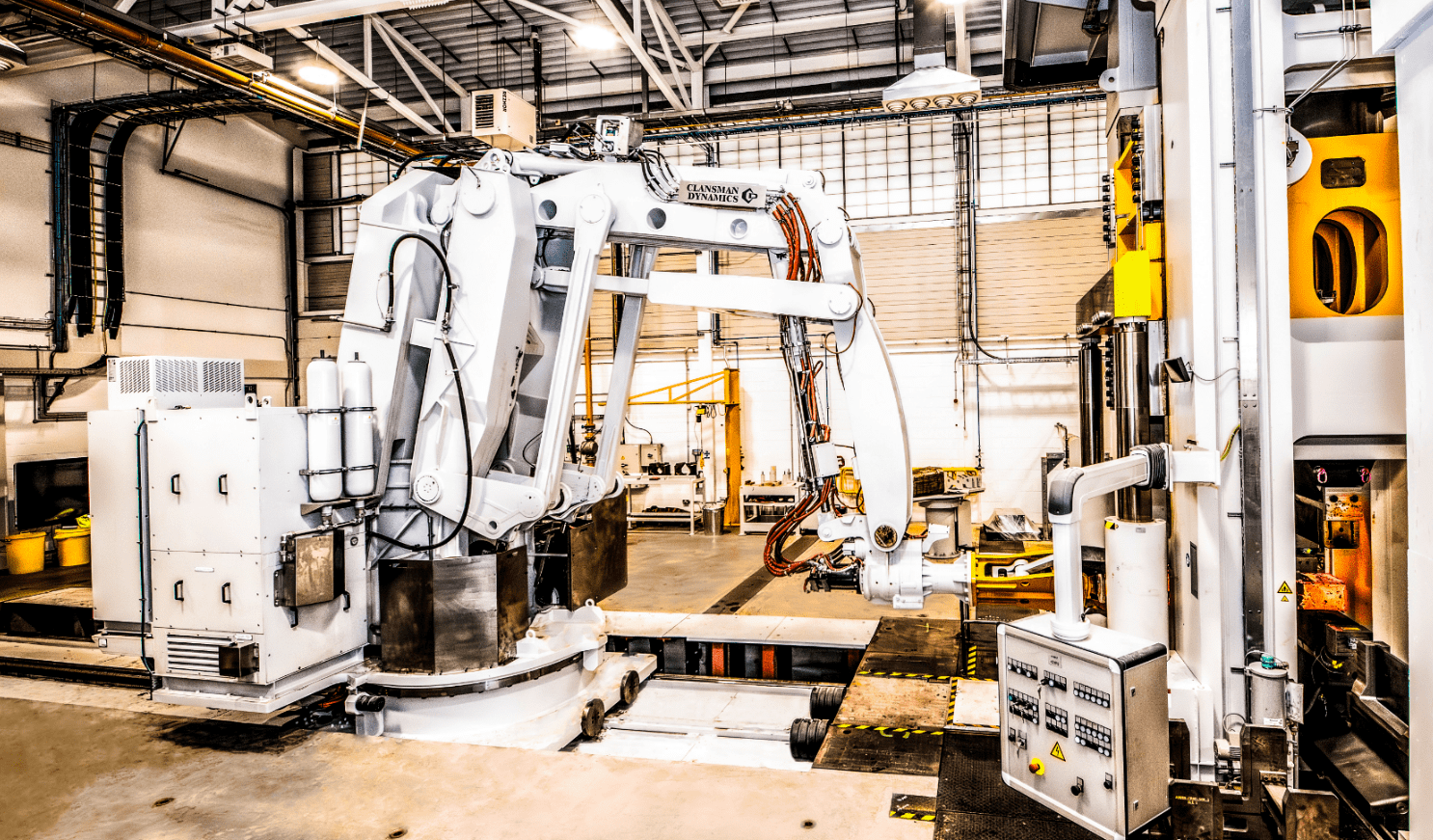

When talking about EcoTitanium, we are talking about Europe, the environment, innovation, and the industry of the future. At the forefront of technology, EcoTitanium is among the few to use plasma fusion in its state-of-the-art facilities to melt titanium ingots. This process allows the removal of a maximum amount of impurities in order to obtain premium quality ingots meeting requirements of the most critical industries such as aerospace.

At full throttle in 2022-2023, EcoTitanium will produce several thousand tons of titanium each year, while consuming 4 times less energy than the conventional route from ore.

21 thousand tons of titanium scrap are exported each year by the European Union. EcoTitanium is taking advantage of this precious resource thus enabling the development of a new circular economy sector in Europe.