Nuclear

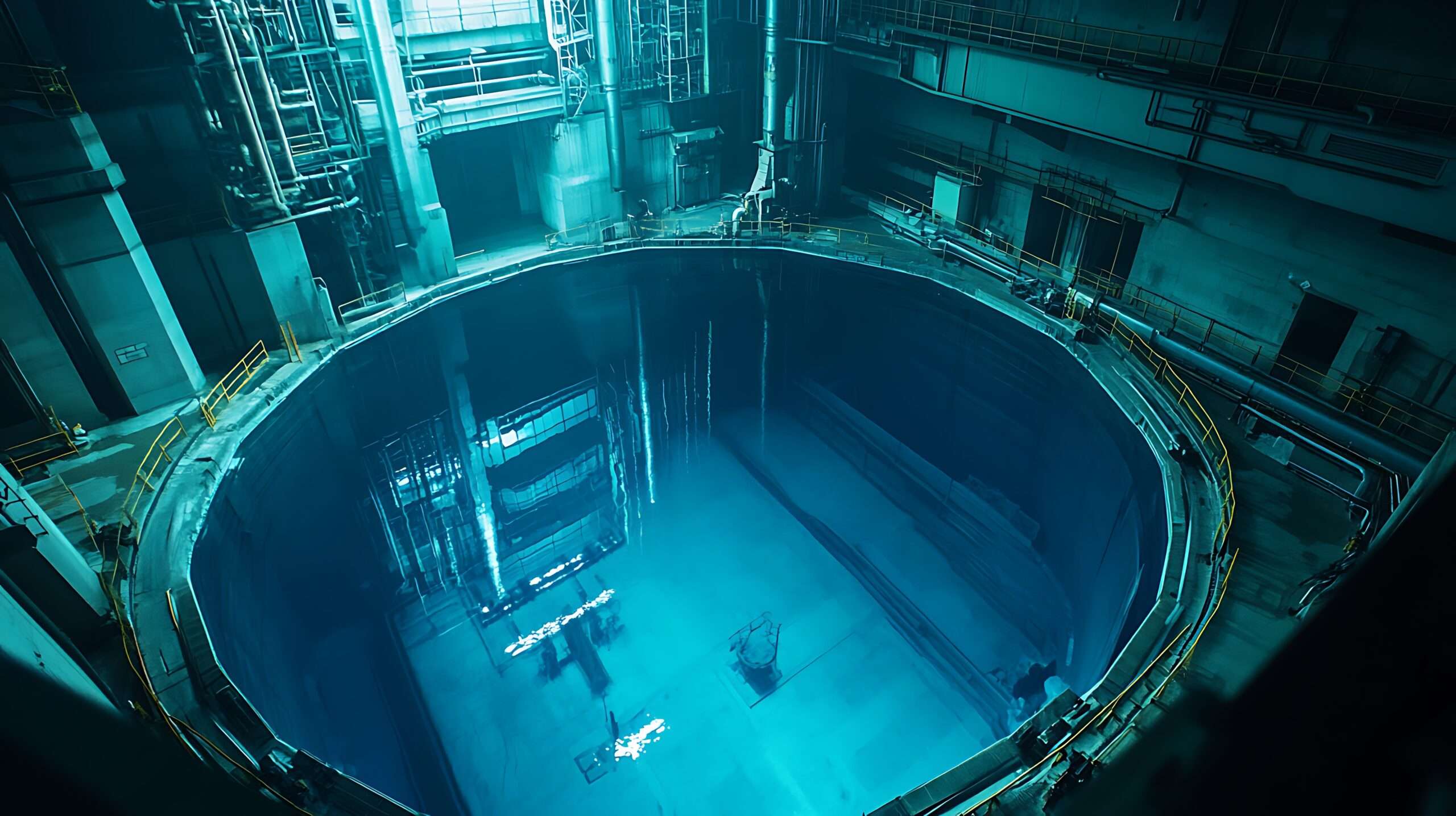

Civil nuclear

Major expertise in critical nuclear applications

For almost 60 years, Aubert & Duval has been developing and supplying steel and superalloy materials and forged parts that meet the most stringent requirements of the nuclear industry in terms of technical performance and quality.

Widely used in the primary circuit of many civil nuclear power plants throughout the world, our materials are also present in experimental reactors such as the RJH, Astrid and ITER, and in submarine nuclear propulsion systems.

Leveraging over a century of metallurgical expertise, Aubert & Duval develops advanced material solutions tailored to the demands of next-generation reactor technologies and concepts.

Our offer

Aubert & Duval produces an extremely wide range of metallurgic solutions in the form of forged or rolled bars, forged parts and powders for additive manufacturing :

- low alloyed and alloyed steels (including low cobalt composition),

- nickel-based superalloys,

The products can be delivered as-forged or pre-machined, or even ready for installation.

Aubert & Duval products cover all types of civil nuclear reactor, Gen II, Gen III and Gen III+, and we are working with our customers on new solutions for advanced Gen IV reactors and for small modular reactors.

Our products are designed and manufactured specifically for reactor internals, primary circuit components and steam generators.

Aubert & Duval is also a major producer of materials used in nuclear fuel cycle, in particular for enrichment and reprocessing manufacturing equipment.

Qualifications

Aubert & Duval works in accordance with the RCC-M, RCC-MR, RCC-MRx standards, and the ASME code, and with numerous customer certifications.

Example materials and applications

- Products in 15-15 Ti alloy (standard designation) for operating conditions that require resistance to high temperatures and corrosion, such as Gen-IV reactor applications.

- Austenitic and martensitic steels for engineered for components operating under high-temperature and highly corrosive conditions.

- Products in NY690 alloy for steam generator applications (e.g. separation plates, flow limiters, tubes).

- Forged pump shafts in 347 stainless steel for primary coolant pumps.

- Bars in alloys 304L, A286, 718 for the nuclear fuel assembly.

- Long products in alloy 316L for the pressurizer balance pipes.

- Parts forged in alloys SA 508 Gr3 and SA 508 Gr4N for reactor nozzles and primary pump flaps.

- Bars in alloy 718 fuel assemblies springs.

- Steel and superalloy powders for additive manufacturing.

Thanks to our advanced melting and remelting processes, we are able to master a wide range of alloy compositions — including ultra-low cobalt formulations — while ensuring optimal metallurgical quality :

- Nickel-based alloys (<150 ppm),

- High performance steels (<300 ppm).

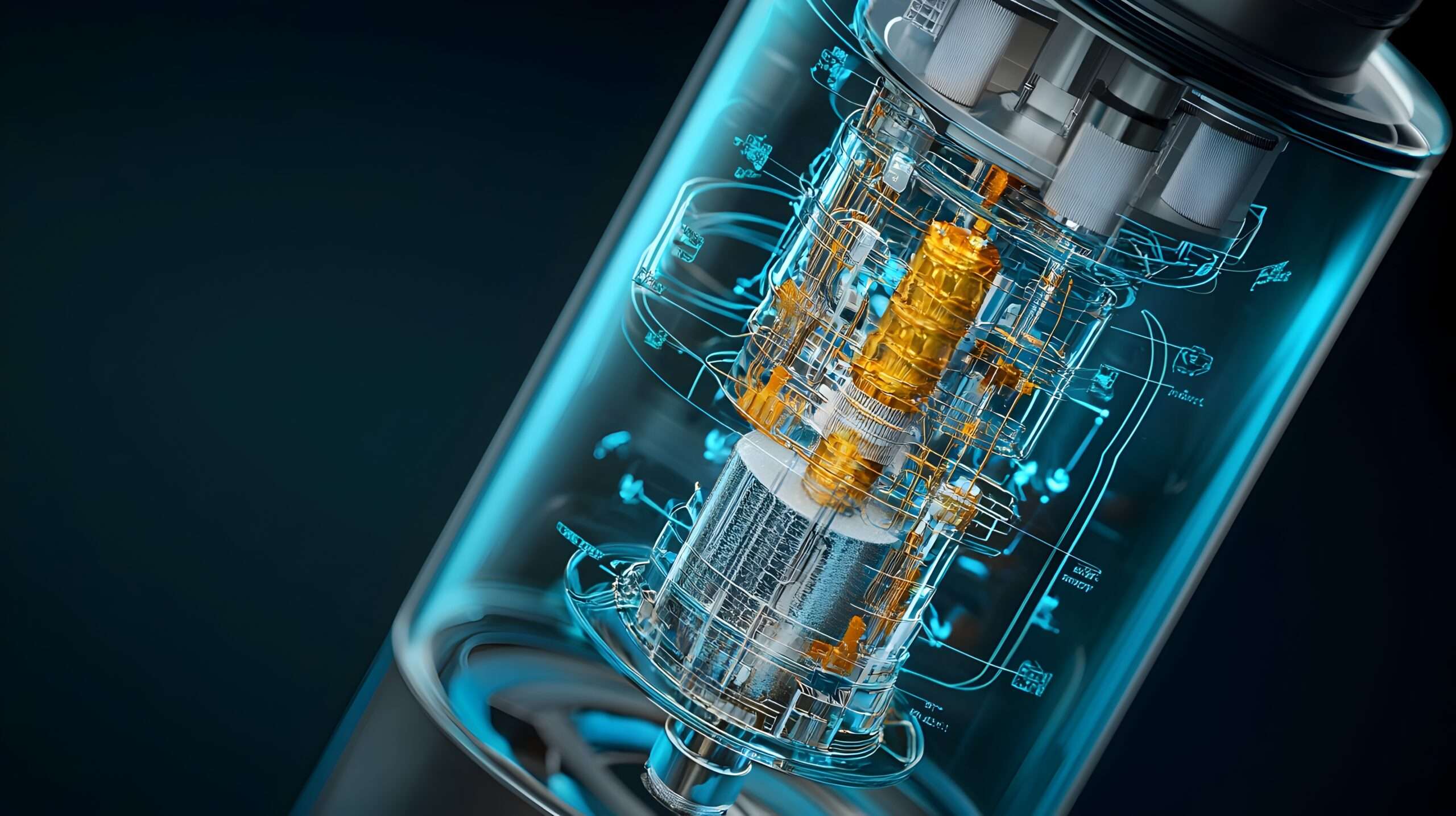

SMALL MODULAR REACTOR

-

Detailed Breakdown of the Fission Process Inside an SMR Small Modular Reactor Nuclear Reactor Core for Efficient and Sustainable Electrical Power